Premium cold‐work die & mold steel whose strength and toughness approach those of high‐speed steels. DC53 steel delivers superior wear resistance and fatigue strength—achieving 62–64 HRC after heat treatment, with roughly twice the toughness of traditional D2—extending tool life in demanding cold‐work applications.

Comparable Standards

| Designation | Grade |

| JIS G4404 | DC53 |

| DIN W.Nr. 1.2990 | 1.2990 Mod. |

| GB/T | Cr12MoV |

Chemical Composition (wt %)

| C | Si | Mn | Cr | Mo | V |

| 0.95 | 1.00 | 0.40 | 8.00 | 2.00 | 0.30 |

Mechanical Properties

| Property | Value |

| Hardness (Brinell) | 210 – 225 HB |

| Hardness (Rockwell C) | 62 – 63 HRC |

| Tensile Strength | 1500 MPa |

| Yield Strength (0.2% offset) | 1300 MPa |

| Modulus of Elasticity | 150 GPa |

| Poisson’s Ratio | 0.28 |

Heat Treatment Guidelines

– Preheating: 800 – 850 °C in vacuum or controlled atmosphere; hold until uniform.

– Austenitizing: 1030 °C, hold 10–20 min.

– Quenching: Air cool or vacuum‐quench.

– Tempering: Double temper at 520 – 530 °C for 2 h per cycle; yields 62 – 63 HRC.

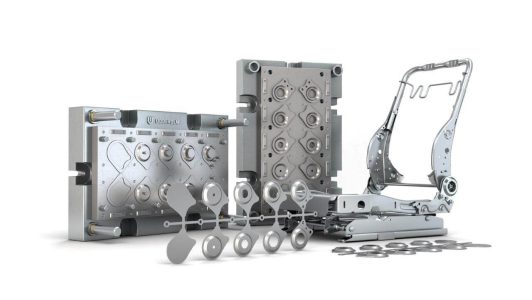

Typical Applications

– Stamping & blanking dies

– Progressive & extrusion tools

– Injection & blow mold inserts

– Cutting tools (shear blades, scissors)

– High‐wear punches & dies

Supply Formats & Services

– Stock Shapes: Rounds (20 – 350 mm Ø), Flats (25 × 50 – 200 × 500 mm), Blocks (up to 2,000 kg)

– Custom Cutting: Precision bandsaw or water‐jet to drawing

– Value-Added Services: In-house forging & heat treatment, UT/MPI inspection, hardness & microstructure analysis, pre-machining, surface grinding

Certifications & Quality Assurance

– Mill-traceable Test Certificates (EN 10204 3.1)

– Ultrasonic & MPI Reports (ASTM A388) on request

– Hardness, Grain-Size & Decarburization Analysis

– ISO 9001:2015 quality system (certification in process)

Logistics & Enquiry

– Same-day Dispatch for stocked items from Kolkata

– 24–48 hr turnaround on cut-to-size orders

– PAN-India insured delivery via leading couriers

– Request a quote: sales@ascforgings.com | +91-XX-XXXXXXX