Comparable Standards

| Designation | Grade |

| DIN W.Nr. 1.2379 | X153CrMoV12 |

| AFNOR | Z160CDV12 |

| AISI/SAE | D2 |

| JIS | SKD11 |

Chemical Composition (wt %)

| C | Si | Mn | P (max) | S (max) | Cr | Mo | V |

| 1.50 – 1.60 | 0.10 – 0.40 | 0.15 – 0.45 | 0.03 | 0.03 | 11.0 – 12.0 | 0.60 – 0.80 | 0.90 – 1.10 |

Mechanical Properties (Annealed / Hardened)

| Property | Value |

| Hardness (annealed) | ~220 HB |

| Hardness (hardened) | 55 – 62 HRC |

| Impact Toughness | 77 J/cm² |

| Poisson’s Ratio | 0.27 – 0.30 |

| Modulus of Elasticity | 190 – 210 GPa |

Physical Properties

| Property | 20 °C | 100 °C | 200 °C | 300 °C |

| Coefficient of Thermal Expansion (10⁻⁶ m/m·K) | 10.6 | 11.5 | 11.8 | 12.3 |

| Thermal Conductivity (W/m·K) | 16.7 | 20.5 | 24.2 | – |

Heat Treatment Guidelines

**Annealing:** Heat to 840 – 870 °C, hold 2 min/mm, furnace cool to 600 °C, then air cool.

**Stress Relieving:** Heat to 650 – 700 °C, hold 2 min/mm, furnace cool.

**Hardening:** Preheat 750 – 800 °C; heat to 1000 – 1050 °C, hold 1 min/mm; quench in air, oil, or salt bath.

**Tempering:** Immediately double-temper at 500 – 550 °C (soak 1 h per 25 mm) for optimal toughness.

Tempering Hardness Chart

| Tempering Temp (°C) | 100 | 200 | 300 | 400 | 500 | 525 | 550 | 600 |

| Hardness (HRC) | 63 | 61 | 58 | 58 | 58 | 60 | 56 | 50 |

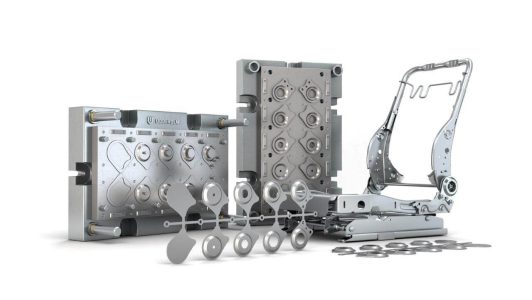

Typical Applications

– Threading rolls & dies

– Cold extrusion tools

– Trimming, cutting & stamping tools (sheet up to 6 mm)

– Precision cutting tools (sheet up to 12 mm)

– Cold pilger mandrels & circular-shear blades

– Deep-drawing dies & pressure pads

– Chipper knives, slitters, shear blades, punches

– High-wear plastic mould inserts & tyre shredders

Supply Formats & Services

– Stocked Shapes: Round bars (20 – 350 mm Ø), flats (25 × 50 – 200 × 500 mm), blocks (up to 2000 kg)

– Custom Cutting: Precision bandsaw cutting to your drawing

– Value-Added Services: In-house forging, heat treatment, ultrasonic & MPI testing, hardness & metallurgical analysis, pre-machining, surface grinding

Certifications & Quality Assurance

– Mill-Traceable Test Certificates (EN 10204 3.1)

– Ultrasonic & MPI Reports (ASTM A388 on request)

– Hardness, Grain-Size & Decarb Analysis

– ISO 9001:2015 (certification in process)

Logistics & Enquiry

Same-day Dispatch for stocked items from Kolkata. 24–48 hr turnaround on custom-sawn materials. Nationwide Delivery via trusted logistics partners.

Enquire Now: sales@ascforgings.com | +91-XX-XXXXXXX